ADDITIVES for Flexible Slabstock Foam applications

We are a global leader in polyurethane additives for flexible slabstock applications. We work in close partnership with the comfort industry by providing optimized products, whilst targeting the lowest possible VOC emissions to generate ‘value’ for our customers.

Polyether

STANDARD POLYETHER SLABSTOCK FOAMS

Defined by the use of a high share of polyether polyols in combination with TDI, the densities of Standard Polyether slabstock foams vary from below 10 kg/m³ for quilt & textile applications, to above 100 kg/m³ for special applications like shoe insoles. With the correct use of additives, defect free slabstock foams is facilitated in continuous machine production or large boxes. Over several decades, we have developed a large variety of different specialized products and a significant number of our additives are found in final consumer applications in the market. In an ever-changing environment, we are committed to producing new surfactants, catalysts and processing additives that improve productivity, performance and help protect the environment.

Among our TEGOSTAB®, DABCO®, TEGOAMIN®, KOSMOS® or ORTEGOL® brands you will find the right additives for your foam formulation, and our technical teams are ready to support you. We look forward to opening a dialogue with you to enter technical discussions for your best additive solution.

Polyester

POLYESTER FOAM

Mainly used for flame-laminated fabrics in automotive markets, and other textile lamination applications, packaging, and filtration, polyester-based foams are often linked to certain technical applications. In contrast to polyether foams, polyester foams have a high natural stability against solvents, but lower stability towards hydrolysis. Polyester foaming requires a different set of additives. For foam stabilizers, the focus is much more on emulsification of the raw materials and less on stabilization compared to ether foaming. Amine catalysts need to support a sufficient cell opening of ester foams. We offer a broad range of silicone surfactants, organic surfactants, emulsifiers, amine catalysts and antioxidants for manufacturing flexible polyester foam. All of these additives are NPE-free (Nonylphenol ethoxylates) and many are optimized for the common VOC and FOG testing criteria.

HR Slabstock

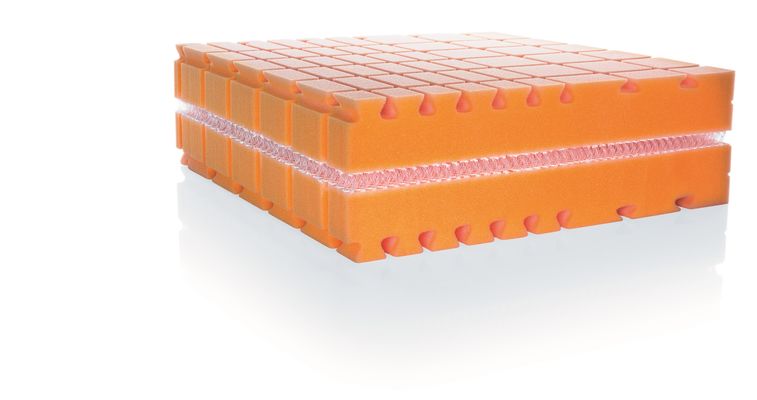

HR SLABSTOCK FOAM

HR foams are characterised by a higher elasticity compared to standard ether foams. The elasticity is measured by ball rebound experiments, or the comfort factor. HR foams are made from special HR polyols with higher molecular weight and higher reactivity. In addition to TDI, MDI is also used frequently as an isocyanate for HR foams. The cell strucutre often needs to be irregular to support the higher elasticity. This is achieved by a special type of foam stabilizer that targets a good cell opening and a cell structure that supports the elasticity. Our additives for HR foams help improve manufacturing, processing and the final foam characteristics, such as stability or cell size. Besides our products, we also offer expertise in developing formulations that meet low emission certificates., Additionally, our wide portfolio of ORTEGOL® products provide support for well-known production issues like cold-flow.

Viscoelastic

VISCOELASTIC SLABSTOCK FOAM

Used in the production of mattresses, topper pads, and pillows, Viscoelastic foams are characterized by a delayed recovery after compression and very low elasticity (ball rebound). These properties are obtained by a special polyol composition or a tight cell structure. The selection of foam stabilizers can be a tricky task for viscoelastic foams as the processing window is usually relatively narrow. We offer a full additives package for this application and expertise in meeting low emission certifications, with our DABCO® NE and TEGOSTAB® product ranges. Our well-known SiOC based TEGOSTAB® silicones offer large processing latitudes in a wide range of TDI based formulations. We also provide ORTEGOL® additives for improved cell opening, and our portfolio additionally includes special products for MDI based formulations.

FR Foams

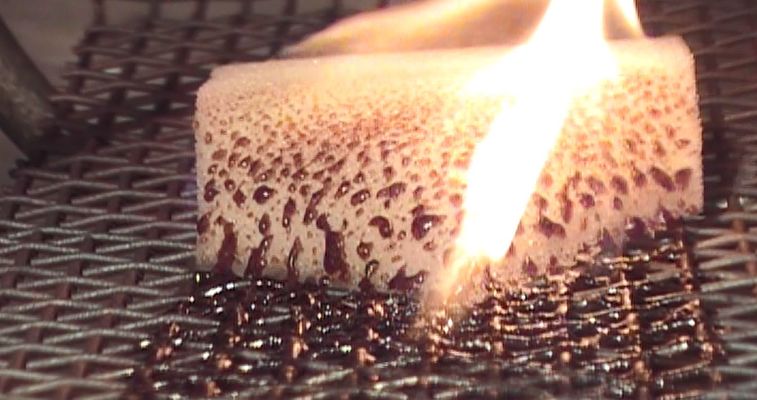

COMBUSTION MODIFIED FOAM

Across the various different foam applications, our customers often require combustion modified foams that are required to pass flammability tests for automotive (MVSS 302), or furniture combustion tests (e.g. BS 5852/Crib V). Usually, by the nature of the raw materials and additives, standard PU foams show high flammability, but by choosing flame retardants, special additives and silicone surfactants, the flammability and weight loss during burning can be dramatically reduced and combustion tests can be passed. Our team has decades of experience in developing modified PU foams, and our global connections help us to fully understand and help your products pass the flammability tests. Our portfolio also consists of additives and surfactants, designed specifically for applications in flame retardant foams. We also provide special ORTEGOL® products that can help improve the foam properties for flame lamination processes.

Additives for flexible polyether block foam - EUROPE